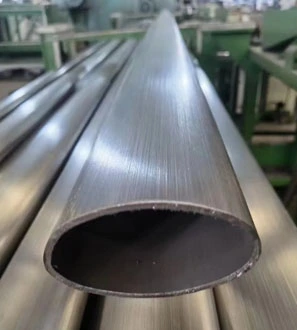

Benefits of Using Titanium Oval Tubing

Titanium oval tubing offers several benefits due to its unique properties. One of the primary benefits is its light weight, which makes it ideal for applications where weight reduction is critical. Additionally, titanium oval tubing has a very high strength-to-weight ratio, meaning it is strong enough to withstand heavy loads while remaining lightweight. The excellent corrosion resistance of titanium also makes it suitable for use in harsh environments such as seawater or acidic solutions. Furthermore, the exceptional biocompatibility of titanium makes it an excellent choice for medical implants. Finally, titanium oval tubing can be easily customized to meet a wide range of specifications, making it a versatile material for various applications. Yeshengti has many custom titanium tubes for sale at competitive price, inquiry now!

WE OFFER

Gr5ELI Titanium Tube

Gr9 Titanium Tube

Gr23 Titanium Tube

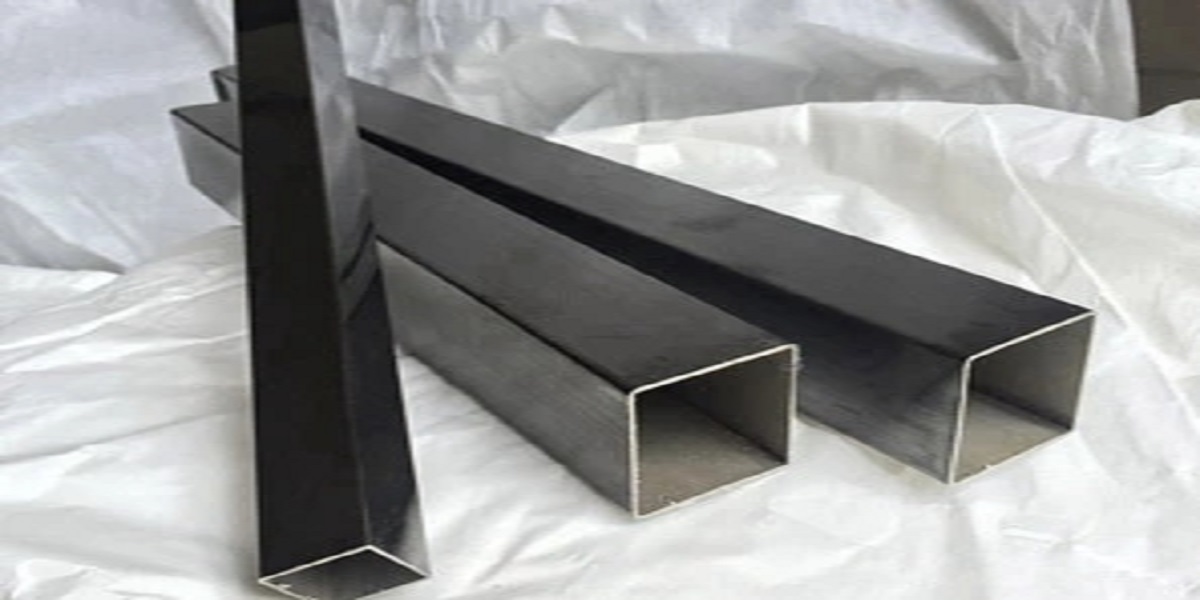

Joining Techniques for Titanium Square Bar

Titanium square bar can be joined using several techniques, including welding, brazing, and mechanical fastening. Welding is the most common method of joining titanium bar due to the material's high strength and durability. However, it is important to use proper heat control and a filler material compatible with the titanium alloy to avoid overheating or weakening the material. Brazing, a low-temperature joining technique, uses an intermediate material to bond two or more metals. Mechanical fastening methods such as bolts, screws, and rivets are also used but require the use of appropriate fasteners to avoid galvanic corrosion. Due to the hazardous nature of machining and welding titanium, proper precautions and protective gear should be used when joining titanium square bar.

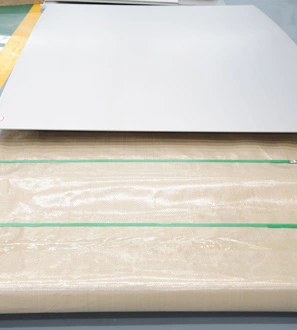

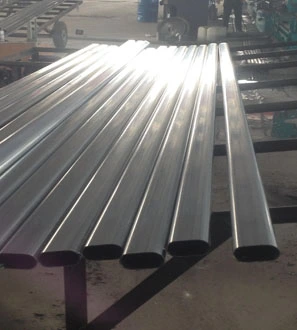

Titanium oval tubing for exhaust systems, lower exhaust pipes, intercooler systems

With Yeshengti titanium factory, Titanium oval tubing is a remarkable material that has found extensive use in the automotive industry, particularly in exhaust systems, lower exhaust pipes, and intercooler systems. The properties of titanium, combined with the unique oval shape, offer several advantages for these applications.

In exhaust systems, titanium oval tubing is prized for its high-temperature resistance and exceptional corrosion resistance, ensuring durability and longevity. Its lightweight nature aids in improving overall vehicle performance and fuel efficiency. Lower exhaust pipes benefit from the oval shape, which allows for more efficient routing and packaging beneath the vehicle while maintaining adequate ground clearance.

Intercooler systems, crucial for optimizing engine performance, rely on titanium oval tubing for its strength and heat resistance. The oval shape facilitates space-saving design, allowing for efficient airflow and cooling. These qualities make it an ideal choice in high-performance and racing vehicles where optimal engine efficiency and power output are paramount.

Titanium oval tubing for exhaust systems and intercooler systems represents a cutting-edge solution that combines durability, performance, and space efficiency, ensuring that vehicles can achieve their full potential while remaining reliable and durable.

More Yeshengti titanium tubes

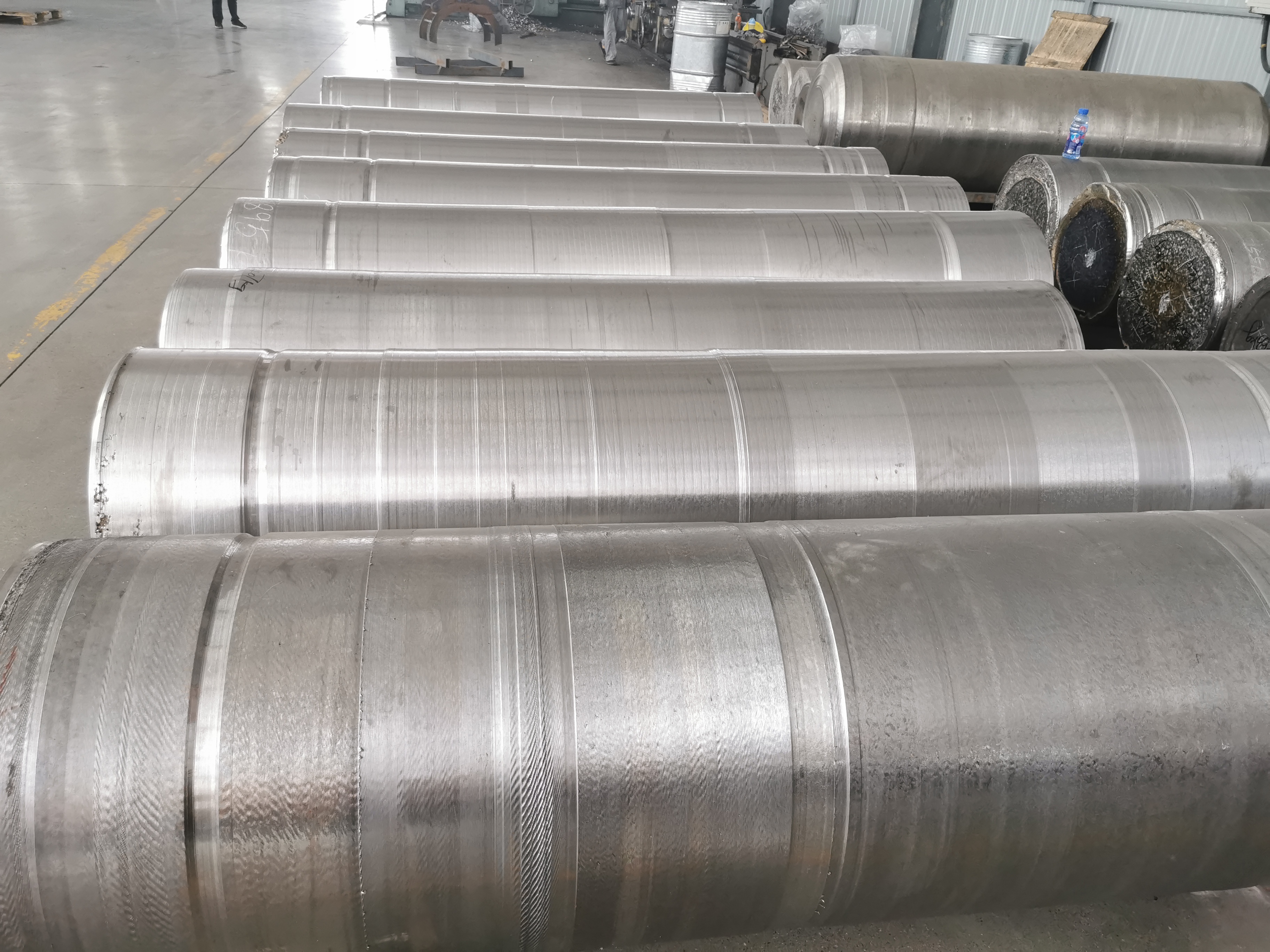

Titanium Seamless Tube

Titanium Welded Pipe

Titanium Rectangular Tubing

Gr5ELI titanium tube is a medical-grade titanium alloy that is widely used in the manufacturing of medical implants due to its excellent biocompatibility and mechanical properties.Gr5ELI Titanium Tube Price

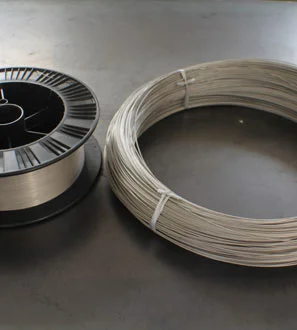

Gr5ELI titanium tube is a medical-grade titanium alloy that is widely used in the manufacturing of medical implants due to its excellent biocompatibility and mechanical properties.Gr5ELI Titanium Tube Price Gr9 titanium tube is a titanium alloy that contains small amounts of palladium, making it an excellent choice for applications requiring high weldability and formability.Gr9 Titanium Tube Price

Gr9 titanium tube is a titanium alloy that contains small amounts of palladium, making it an excellent choice for applications requiring high weldability and formability.Gr9 Titanium Tube Price Gr23 titanium tube is a titanium alloy that contains aluminum and vanadium, making it an excellent material for medical implants due to its low weight and biocompatibility.Gr23 Titanium Tube Price

Gr23 titanium tube is a titanium alloy that contains aluminum and vanadium, making it an excellent material for medical implants due to its low weight and biocompatibility.Gr23 Titanium Tube Price English

English