Thank you for your

attention on Yesheng !

3 Inch Titanium Tube Manufacturing Process

The manufacturing process of a 3-inch titanium pipe involves several steps, including raw material preparation, forming the pipe, heat treatment, machining and finishing, and quality control.

Raw Material Preparation of 3 Inch Titanium Pipe

The first step of manufacturing a 3-inch titanium pipe is to prepare the raw material. Titanium is a reactive metal with a high affinity for oxygen, so it must be handled in an oxygen-free environment. Therefore, the titanium sponge or pure titanium powder is transferred to a vacuum arc furnace or a plasma furnace, where it is melted and alloyed with other metals like aluminum and vanadium. The resulting ingot is then taken to a hot rolling mill, where it is reduced to a billet of the required diameter and length for further processing.

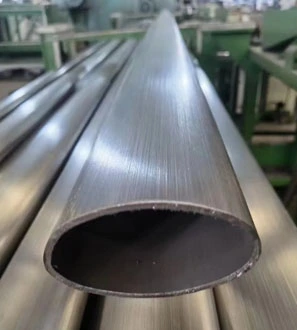

Forming the Pipe 3 Inch Titanium Pipe

After the billet is cut to the required length, it is heated to the desired temperature and then fed into a piercing mill. Here, the billet is pierced with a mandrel inserted at the center to create a hollow tube. Then the tube is passed through a sequence of dies of decreasing diameter to achieve the desired outer diameter and wall thickness of the pipe. Depending on the application, the pipe may undergo multiple stages of cold rolling, hot sizing, or drawing.

Heat Treatment 3 Inch Titanium Pipe

The formed pipe is then heat treated to optimize its mechanical properties and remove any impurities. The pipe is heated to a specific temperature depending on the alloy composition and maintained at that temperature for several hours. This process helps to reduce residual stress, improve ductility and toughness, and enhance corrosion resistance. After heat treatment, the pipe is annealed in a vacuum or inert gas to prevent it from reacting with oxygen and to release any residual stress.

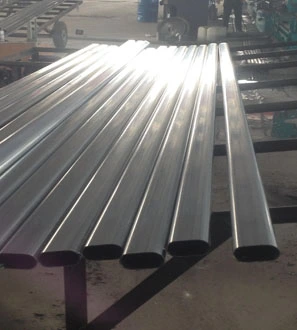

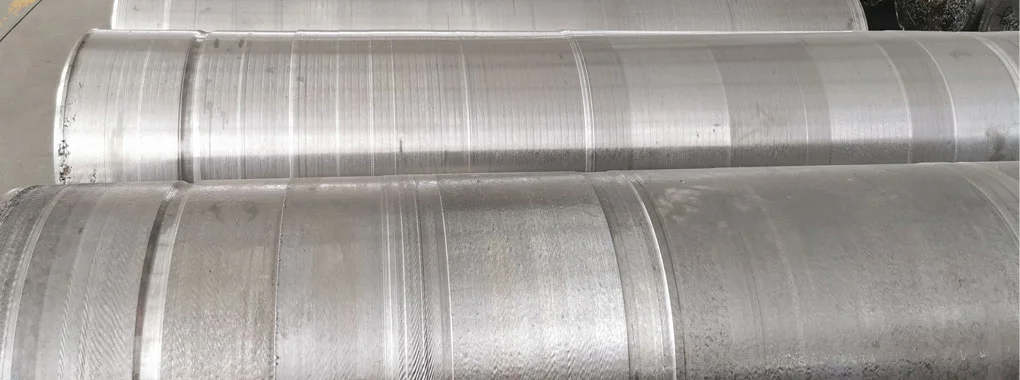

Machining and Finishing 3 Inch Titanium Pipe

The next stage involves machining the pipe to meet the final dimensional requirements. This includes cutting the pipe to the required length and shaping the ends according to the customer's specifications. The pipe may also undergo further processing such as polishing, grinding, or blasting to achieve a smooth surface finish. In some cases, the pipe may be coated with a protective layer of oxide or a nitride to further enhance corrosion resistance.

Quality Control 3 Inch Titanium Pipe

Finally, the pipe is subjected to rigorous quality control tests to ensure it meets the required specifications. These tests may include non-destructive methods such as ultrasonic or X-ray inspection to check for internal defects and wall thickness variations. The pipe may also undergo mechanical testing to measure tensile strength, hardness, and elongation. Further tests may be conducted to determine the metallurgical properties such as microstructure, grain size, and composition. After the testing is complete, the pipe is packaged and shipped to the customer. Yeshengti offer seamless titanium alloy pipe and titanium welded pipe at custom designs and sizes.

Manufacturing a 3-inch titanium pipe requires several steps, including raw material preparation, forming the pipe, heat treatment, machining and finishing, and quality control. Each step must be carried out with great care and precision to ensure the final product meets the required specifications and is suitable for the intended application. Contact Yeshengti for competitive titanium tubing for sale!

English

English