Thank you for your

attention on Yesheng !

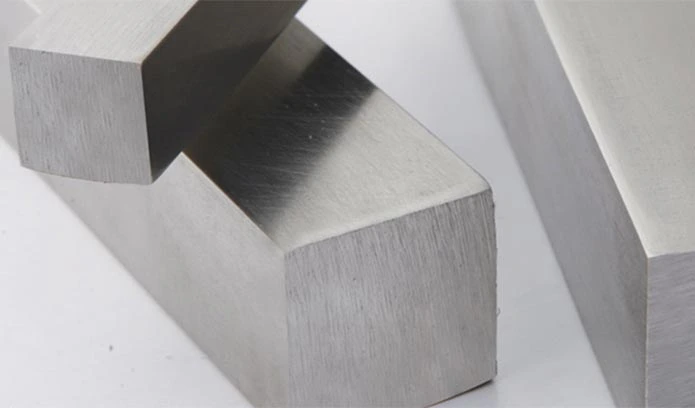

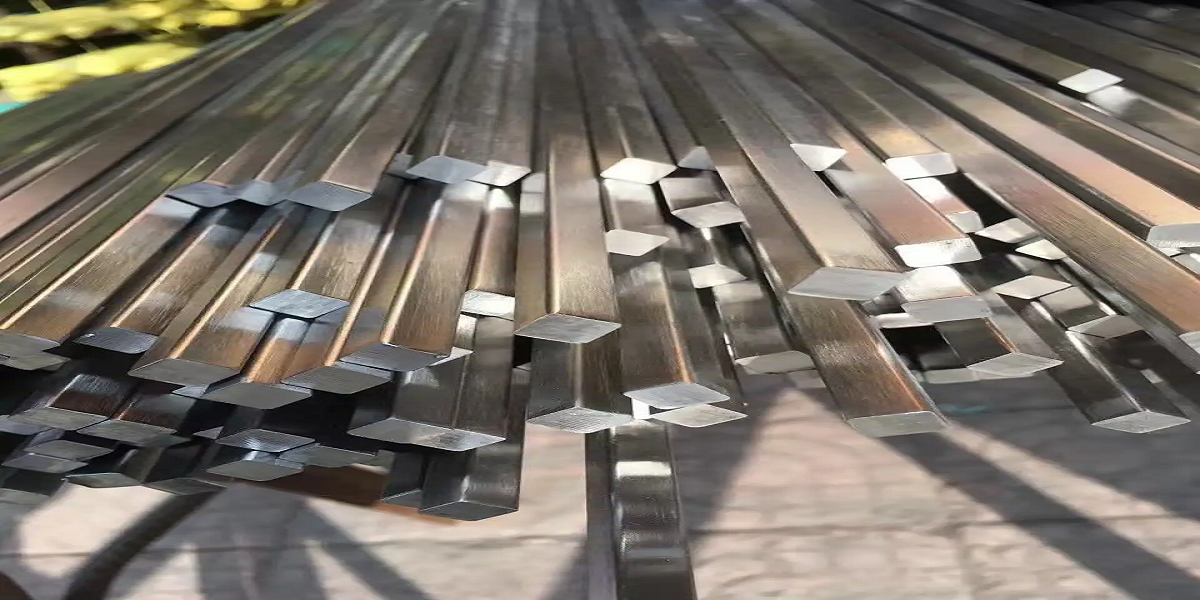

Titanium Forgings and GR1 Titanium Billet Uses in Petroleum Industry

The petroleum industry, with its demanding conditions and corrosive environments, finds an unparalleled ally in Titanium Forgings and Gr1 Titanium Billets. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and non-magnetic properties, these materials play a pivotal role across various facets of the petroleum sector.

GR1 Titanium Billet for Drilling Rig Components

Titanium forgings and Gr1 Titanium billet take center stage in the construction of drilling rig components. Their capability to withstand extreme conditions and harsh environments makes them indispensable for ensuring the robustness and durability of drilling operations.

Drilling Pipe

Titanium alloy drill pipes, featuring high resistance to corrosion and erosion, become the cornerstone for drilling in saltwater environments and corrosive formations. Their lightweight nature not only enhances drilling efficiency but also contributes to improved maneuverability of the drilling equipment.

Wellhead Components

In various wellhead components, including valves, casings, and manifolds, forge welding titanium proves its mettle by withstanding high pressures, elevated temperatures, and corrosive fluids. The non-magnetic properties of Titanium make it particularly suitable for applications where magnetic interference poses concerns.

Jackets and Rig Bodies

Titanium forgings and custom titanium products step into the construction of jackets and rig bodies, providing the necessary strength to withstand the immense forces and stresses encountered during drilling operations. The lightweight design of Titanium components further enhances the stability and maneuverability of drilling rigs.

Subsea Applications

Titanium's superior corrosion resistance finds increasing utilization in subsea applications such as risers, flowlines, and production structures. Its ability to withstand the harsh underwater environment positions it as a reliable choice for critical components.

GR1 Titanium Billet for Refining and Processing Equipment

Storage Tanks and Vessels

Widely adopted in the petroleum industry, Titanium storage tanks and vessels offer resistance to corrosion from various chemicals and fuels. The lightweight construction not only ensures durability but also reduces transportation and installation costs.

Heat Exchangers

Titanium's high temperature tolerance and resistance to corrosive environments make it an ideal material for heat exchangers. The efficiency in transferring heat further establishes Titanium's role in enhancing the performance of refining and processing equipment.

Pumps and Valves

In the realm of pumps and valves used in petroleum refining processes, Titanium shines with its resistance to corrosion and wear. The high strength-to-weight ratio of Titanium contributes to the overall efficiency of these crucial components.

GR1 Titanium Billet for Petroleum Exploration Equipment

Sonar Domes

Titanium takes on the challenge of constructing sonar domes for underwater exploration. Its high strength, corrosion resistance, and ability to withstand deepwater pressures position it as a reliable material for critical exploration equipment.

Offshore Drilling Platforms

Various components of offshore drilling platforms, including risers, anchors, and walkways, benefit from Titanium's high strength, corrosion resistance, and ability to withstand saltwater and marine environments.

Environmental Monitoring Equipment

Titanium's resistance to corrosion and its ability to withstand harsh environments make it a preferred choice for manufacturing environmental monitoring equipment, including sensors and probes.

Titanium Forgings and Gr1 Titanium Billets emerge as indispensable assets in various aspects of the petroleum industry. For competitive titanium billet cost direct from China titanium billet manufacturing company, contact Yeshengti. Their exceptional properties, ranging from strength-to-weight ratio to corrosion resistance, make them essential for ensuring the safe and efficient extraction, processing, and transportation of oil and gas. As the demand for petroleum resources continues to rise, Titanium's role in the petroleum industry is poised for further expansion, cementing its status as a pinnacle material for the challenges of this dynamic sector.

English

English