Thank you for your

attention on Yesheng !

Unraveling the Titanium Ingot Process

The Birth of Titanium: Extracting the Raw Material

Titanium, a versatile and sought-after metal, begins its journey from the depths of the Earth. The primary source of titanium is mineral sands, where titanium-containing minerals undergo a series of extraction processes. This includes crushing, grinding, and magnetic separation to isolate the titanium-rich ore. The extracted material is then processed through complex chemical methods to produce titanium dioxide, a crucial precursor for the production of titanium metal.

From Powder to Precision: The Titanium Sponge Stage

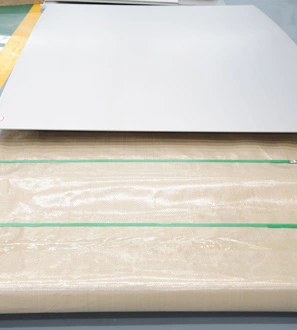

Once titanium dioxide is obtained, it undergoes a transformation into titanium sponge—a porous, high-purity form of titanium. This initial step in the ingot manufacturing process involves the reduction of titanium tetrachloride with magnesium, resulting in the formation of porous titanium metal. The resulting titanium sponge retains the metal's inherent strength and lightweight properties, setting the stage for the creation of high-quality titanium ingots.

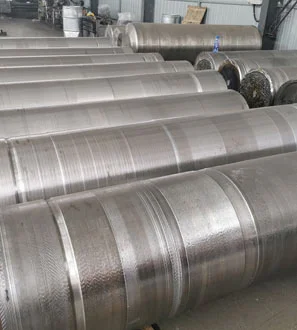

Melting, Forming, and Shaping: Casting Titanium Ingots

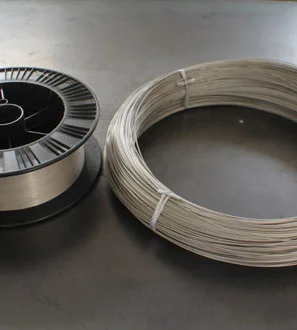

The heart of the titanium ingot manufacturing process lies in the casting phase. The titanium sponge is carefully melted in a vacuum or inert gas environment to prevent contamination and achieve the desired purity levels. This molten titanium is then cast into large, solid forms known as ingots through various casting techniques such as the consumable electrode or skull melting methods.

The casting process demands precision to ensure the ingots meet stringent quality standards. Intricate control of temperature, cooling rates, and the removal of impurities are critical factors in producing titanium ingots with the desired mechanical properties. As the molten metal solidifies within the mold, the ingot takes shape, ready to undergo further processing.

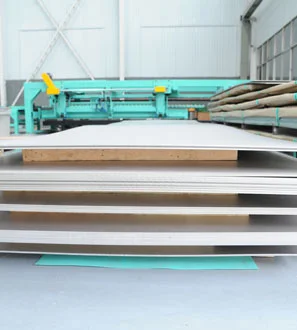

Refining and Finalizing: Perfecting the Titanium Ingot

Following the initial casting, the titanium ingot undergoes refining processes to enhance its purity and remove any remaining impurities. This refining may involve additional melting stages or advanced techniques such as electron beam refining. The goal is to achieve the specific chemical composition required for the intended applications of the titanium ingot.

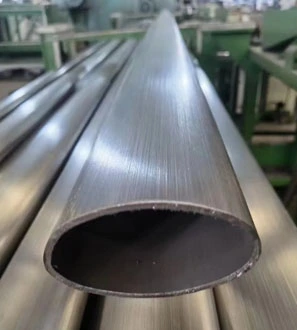

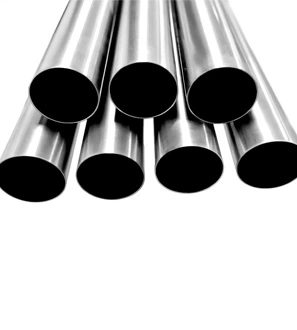

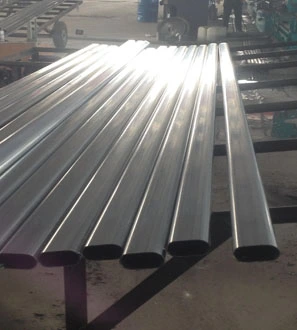

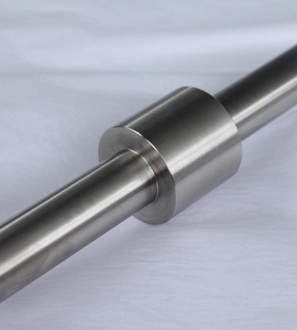

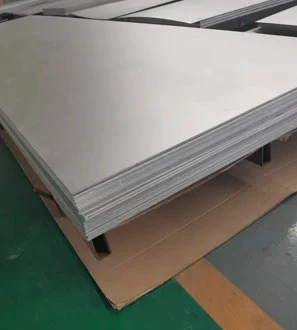

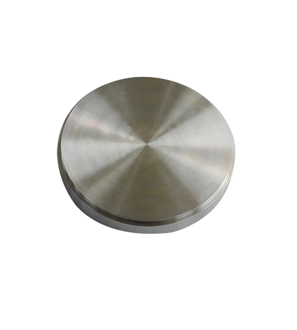

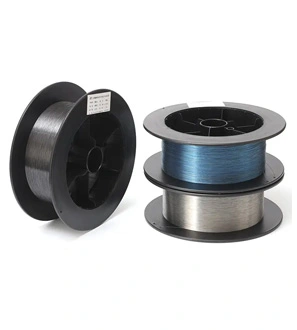

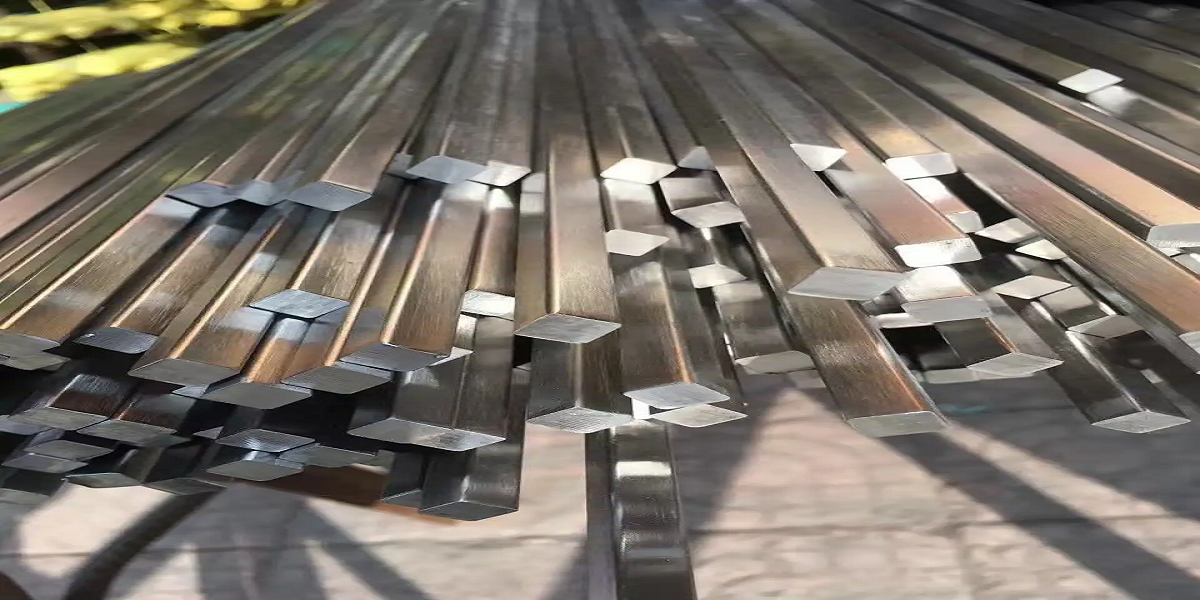

The final step involves shaping the ingot into its desired form, whether for further processing into components or for direct use in specific applications. Precision machining, forging, or extrusion processes can be employed to craft the titanium ingot into the required dimensions. This phase demands careful attention to detail, ensuring that the ingot meets the exact specifications needed for its intended purpose.

The production of titanium ingots is a remarkable intersection of science and craftsmanship. From the extraction of titanium ore to the meticulous casting and refining processes, each step plays a pivotal role in shaping this exceptional metal. The resulting titanium ingots, with their high strength, corrosion resistance, and lightweight characteristics, serve as the foundation for groundbreaking advancements in aerospace, medical, and various other industries. As technology and innovation continue to drive the evolution of materials, the titanium ingot process remains a fascinating journey, uncovering the immense potential of this extraordinary metal.

English

English