Thank you for your

attention on Yesheng !

How Choose Billet Titanium

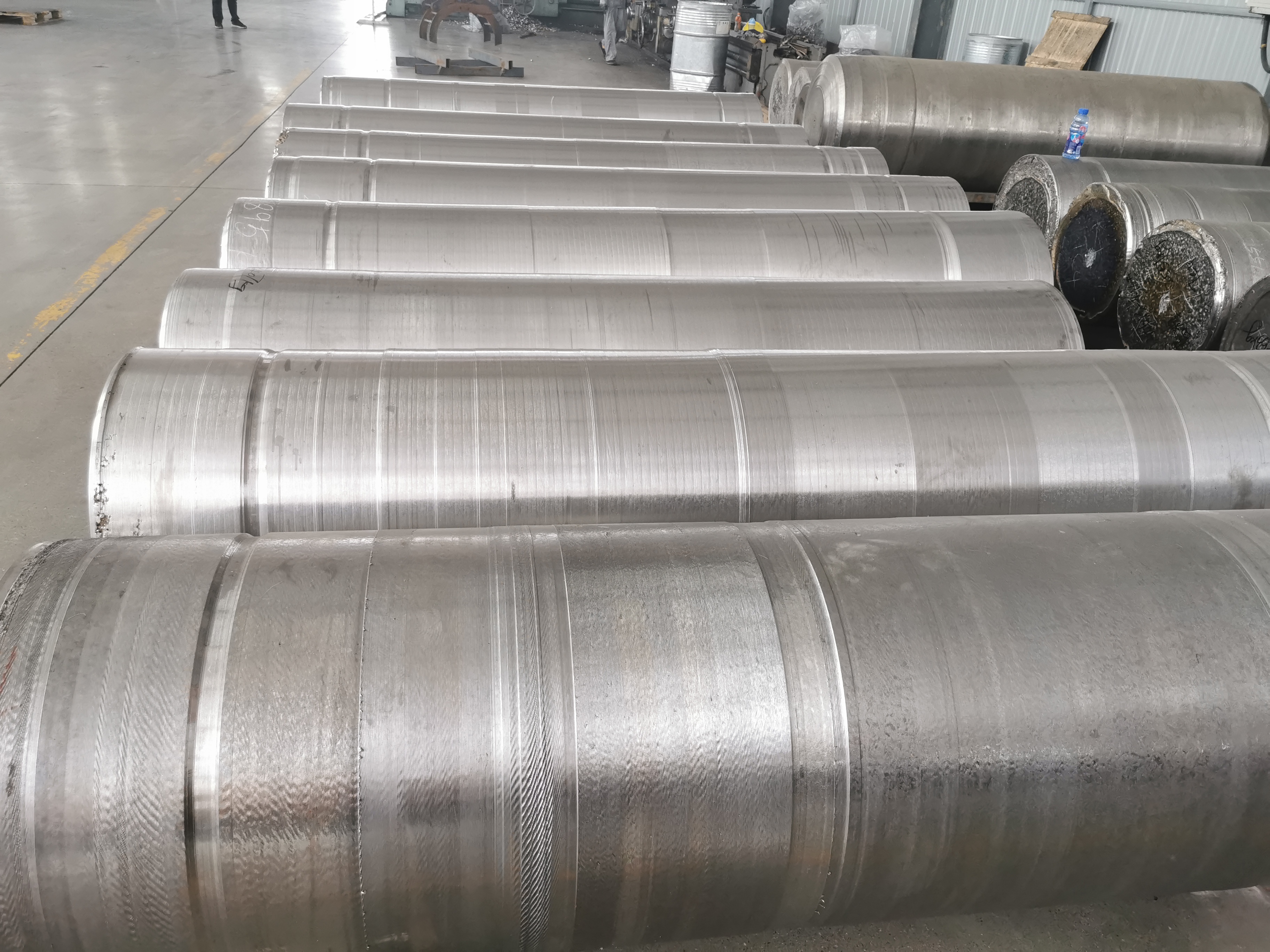

In the realm of high-performance engineering, the choice of materials is paramount. When it comes to applications demanding strength, durability, and lightweight characteristics, billet titanium emerges as a top contender. Whether for billet titanium connecting rods, blocks, or crankshafts, selecting the right material is critical for achieving optimal performance. In this guide, we explore the key factors to consider when choosing billet titanium, ensuring the success of your engineering endeavors.

Understanding Billet Titanium: The Foundation of Performance

Billet titanium represents a pinnacle in material engineering, prized for its exceptional strength-to-weight ratio and corrosion resistance. From aerospace components to high-performance automotive parts, billet titanium serves as the backbone of advanced engineering projects. Its superior mechanical properties make it an ideal choice for applications where reliability and performance are paramount.

Key Considerations in Selection

Material Composition: Not all billet titanium is created equal. Understanding the composition of the material is crucial for ensuring suitability to your specific application. Different alloys offer varying degrees of strength, toughness, and temperature resistance. Consultation with materials experts or suppliers such as Yesheng Titanium Industry can help in identifying the most suitable alloy for your requirements.

Quality and Purity: The quality and purity of the billet titanium significantly impact its mechanical properties and machinability. Opting for high-quality billet titanium from reputable manufacturers like Yesheng Titanium Industry ensures consistency and reliability in performance.

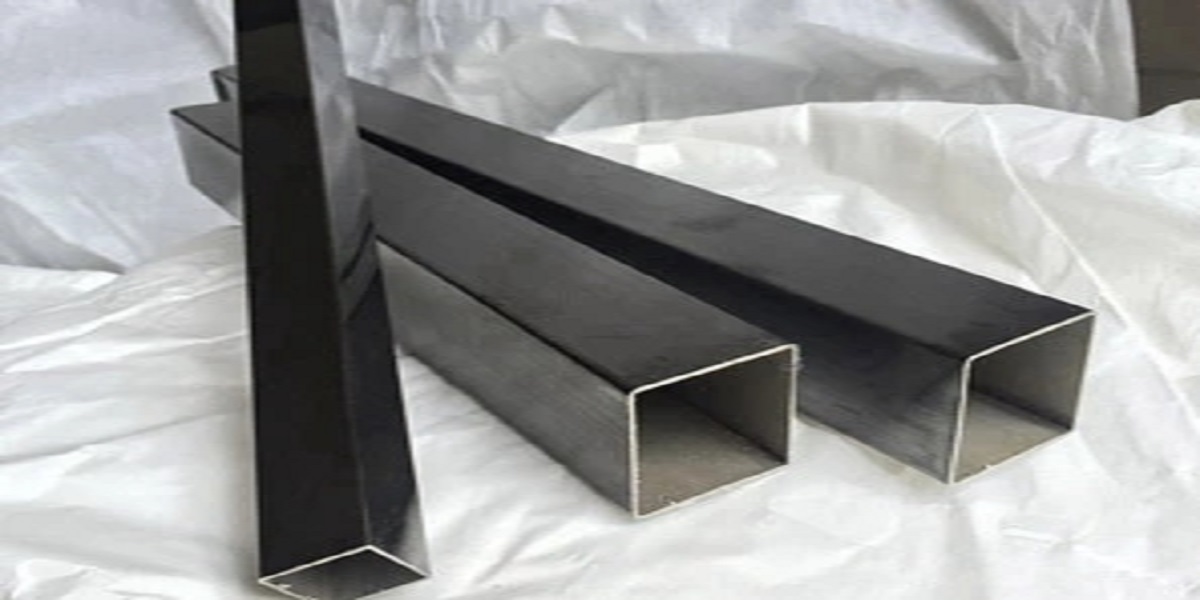

Dimensional Accuracy: Precision engineering often demands tight tolerances and dimensional accuracy. When selecting billet titanium, ensure that it meets the required specifications for size, shape, and surface finish to facilitate machining and assembly processes.

Application-Specific Requirements: Consider the specific demands of your application when choosing billet titanium. For instance, billet titanium connecting rods require exceptional strength and fatigue resistance, while billet titanium blocks may need to withstand high temperatures and corrosive environments. Tailoring the material selection to match the application requirements is essential for optimal performance and longevity.

Partnering with Yesheng Titanium Industry

Yesheng Titanium Industry stands as a leading provider of high-quality billet titanium products, trusted by engineers and manufacturers worldwide. With a commitment to excellence and a track record of delivering premium-grade materials, Yesheng Titanium Industry offers a comprehensive range of billet titanium solutions tailored to meet diverse industry needs.

In conclusion, the selection of billet titanium is a critical decision that can significantly impact the performance and reliability of engineered components. By considering factors such as material composition, quality, dimensional accuracy, and application-specific requirements, engineers and manufacturers can make informed decisions when choosing billet titanium. Partnering with reputable suppliers like Yesheng Titanium Industry ensures access to high-quality materials and expertise, setting the stage for success in even the most demanding engineering projects.

English

English