Thank you for your

attention on Yesheng !

Titanium Manufacturing: Advancements and Challenges

Innovations in Titanium

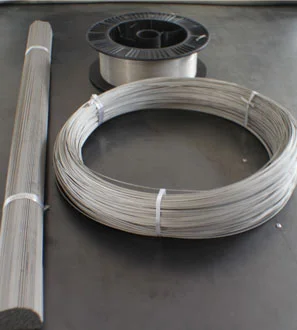

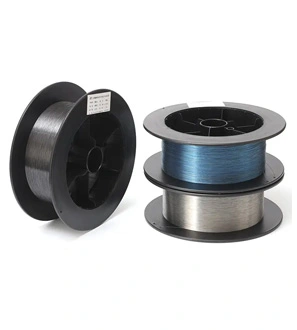

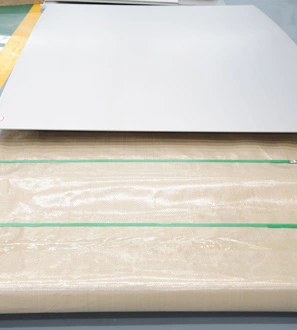

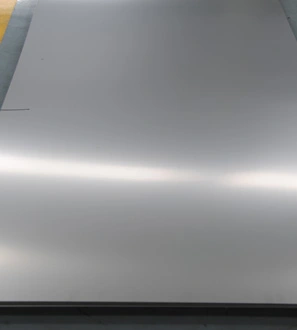

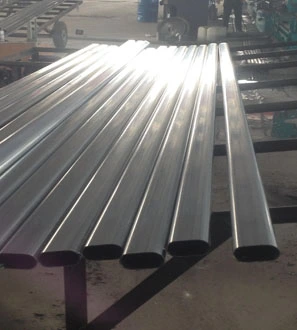

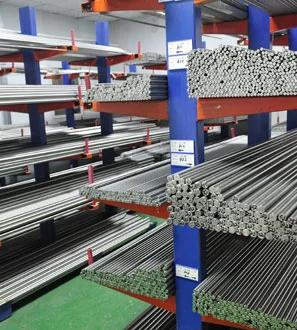

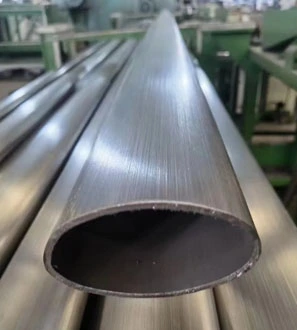

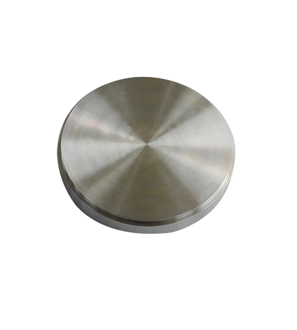

The titanium manufacturing industry has witnessed significant advancements in recent years, particularly in the development of innovative titanium alloys. These alloys play a crucial role in various sectors, including aerospace, medical, and automotive industries. Engineers and researchers have been tirelessly working to enhance the mechanical properties, corrosion resistance, and overall performance of custom titanium products. The incorporation of elements such as aluminum, vanadium, and nickel has led to the creation of high-strength, lightweight alloys that meet the stringent requirements of modern applications.

One notable breakthrough is the development of beta titanium alloys, which exhibit a unique combination of strength and formability. These aerospace titanium alloys are particularly sought after in aerospace engineering, where the demand for lightweight materials with exceptional strength is paramount. The aerospace industry's pursuit of fuel efficiency and performance has driven the adoption of these advanced titanium alloys in the production of aircraft components, contributing to the overall efficiency and safety of air travel.

Sustainable Titanium Production

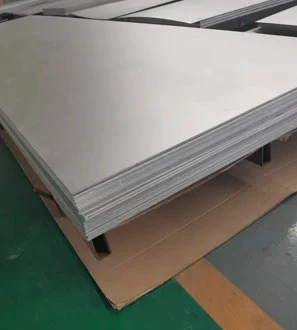

As the global emphasis on sustainability grows, the titanium manufacturing industry faces the challenge of minimizing its environmental impact. Traditional titanium extraction processes have been resource-intensive and energy-consuming. However, there is a growing shift towards more sustainable practices. Researchers are exploring greener alternatives, such as the use of environmentally friendly solvents and renewable energy sources in the extraction and processing of titanium ore.

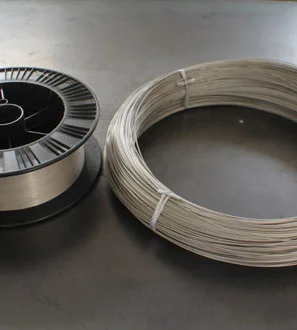

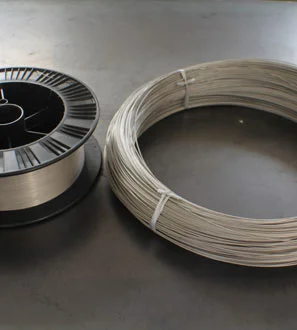

Additionally, recycling has become a focal point in the industry's sustainability efforts. Titanium scrap and waste from manufacturing processes are being increasingly recycled to reduce the demand for virgin titanium resources. This not only conserves valuable raw materials but also decreases energy consumption and carbon emissions associated with primary titanium production.

Challenges and Future Prospects

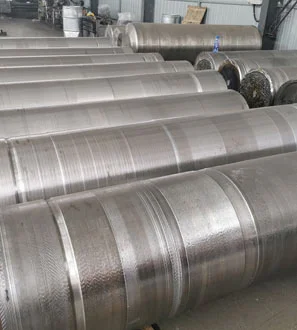

Despite the remarkable advancements, the titanium manufacturing industry faces several challenges that warrant attention. One significant hurdle is the high cost associated with the production of titanium. The extraction, refining, and alloying processes are intricate and energy-intensive, contributing to the elevated cost of titanium products. Researchers and manufacturers are actively exploring cost-effective methods to make titanium more accessible, with a focus on optimizing existing processes and exploring alternative sources of titanium.

Another challenge lies in the limited availability of titanium resources. The majority of titanium is derived from mineral sands, and geopolitical factors can influence the supply chain. Diversification of titanium sources, including exploration of unconventional deposits and recycling initiatives, is crucial for ensuring a stable and reliable supply of titanium for the manufacturing industry.

In conclusion, the titanium manufacturing industry is undergoing a transformative phase with notable advancements in alloy development and sustainability practices. The integration of innovative titanium alloys in various industrial sectors demonstrates the material's versatility and adaptability. However, challenges such as cost and resource limitations necessitate ongoing research and collaborative efforts within the industry to ensure a sustainable and prosperous future for titanium manufacturing.

English

English