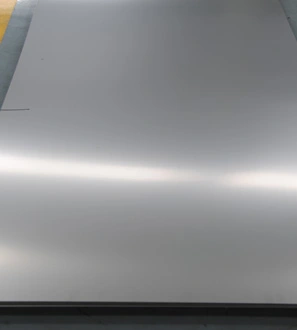

Titanium Sheet/Plate Titanium Sheet/Plate Stock

Titanium sheet/plate is flat rolled titanium that is used for various purposes, including aerospace, engineering, and medical applications. Titanium sheets are made from billets or ingots that are melted, rolled, and cut into sheets of desired thickness. They are known for their high strength-to-weight ratio, corrosion resistance, and thermal stability.

Types of Titanium Sheet/Plate

-

Gr1 Titanium Plate is a commercially pure titanium sheet with excellent corrosion resistance and high strength-to-weight ratio, commonly used in various industries.Gr1 Titanium Plate Price

Gr1 Titanium Plate is a commercially pure titanium sheet with excellent corrosion resistance and high strength-to-weight ratio, commonly used in various industries.Gr1 Titanium Plate PriceGr1 Titanium Plate

-

Gr2 Titanium Plate is a commercially pure titanium sheet with good strength, formability, and corrosion resistance, suitable for numerous industrial applications.Gr2 Titanium Plate Price

Gr2 Titanium Plate is a commercially pure titanium sheet with good strength, formability, and corrosion resistance, suitable for numerous industrial applications.Gr2 Titanium Plate PriceGr2 Titanium Plate

-

Gr3 Titanium Plate is a commercially pure titanium sheet with enhanced corrosion resistance, making it suitable for applications in chemical processing and marine environments.Gr3 Titanium Plate Price

Gr3 Titanium Plate is a commercially pure titanium sheet with enhanced corrosion resistance, making it suitable for applications in chemical processing and marine environments.Gr3 Titanium Plate PriceGr3 Titanium Plate

-

Gr4 Titanium Plate is a commercially pure titanium sheet with higher strength and improved corrosion resistance compared to Gr2, suitable for various industrial applications.Gr4 Titanium Plate Price

Gr4 Titanium Plate is a commercially pure titanium sheet with higher strength and improved corrosion resistance compared to Gr2, suitable for various industrial applications.Gr4 Titanium Plate PriceGr4 Titanium Plate

-

Gr5 Titanium Plate is a titanium alloy sheet made of 6% aluminum and 4% vanadium, known for its high strength, low weight, and exceptional corrosion resistance.Gr5 Titanium Plate Price

Gr5 Titanium Plate is a titanium alloy sheet made of 6% aluminum and 4% vanadium, known for its high strength, low weight, and exceptional corrosion resistance.Gr5 Titanium Plate PriceGr5 Titanium Plate

-

Gr5ELI Titanium Plate is a medical-grade titanium alloy sheet with the same composition as Gr5, specially designed for biomedical applications with enhanced biocompatibility properties.Gr5ELI Titanium Plate Price

Gr5ELI Titanium Plate is a medical-grade titanium alloy sheet with the same composition as Gr5, specially designed for biomedical applications with enhanced biocompatibility properties.Gr5ELI Titanium Plate PriceGr5ELI Titanium Plate

-

Gr9 Titanium Plate is a titanium alloy sheet composed of 3% aluminum and 2.5% vanadium, known for its high strength-to-weight ratio and excellent corrosion resistance.Gr9 Titanium Plate Price

Gr9 Titanium Plate is a titanium alloy sheet composed of 3% aluminum and 2.5% vanadium, known for its high strength-to-weight ratio and excellent corrosion resistance.Gr9 Titanium Plate PriceGr9 Titanium Plate

-

Gr23 Titanium Plate is a titanium alloy sheet composed of 6% aluminum and 4% vanadium, offering excellent corrosion resistance and high strength properties, commonly used in aerospace and medical applications.Gr23 Titanium Plate Price

Gr23 Titanium Plate is a titanium alloy sheet composed of 6% aluminum and 4% vanadium, offering excellent corrosion resistance and high strength properties, commonly used in aerospace and medical applications.Gr23 Titanium Plate PriceGr23 Titanium Plate

-

A Titanium Heat Exchanger Plate refers to a plate made of titanium used in heat exchangers due to its corrosion resistance and thermal conductivity.Titanium Heat Exchanger Plate Price

A Titanium Heat Exchanger Plate refers to a plate made of titanium used in heat exchangers due to its corrosion resistance and thermal conductivity.Titanium Heat Exchanger Plate PriceTitanium Heat Exchanger Plate

-

The Yeshengti 0.5 mm titanium sheet is a high-quality, corrosion-resistant material. Ideal for aerospace, medical, and industrial applications, it offers excellent strength-to-weight ratio and durabil...0.5 mm Titanium Sheet Price

The Yeshengti 0.5 mm titanium sheet is a high-quality, corrosion-resistant material. Ideal for aerospace, medical, and industrial applications, it offers excellent strength-to-weight ratio and durabil...0.5 mm Titanium Sheet Price0.5 mm Titanium Sheet

-

Even at 1mm thin, titanium offers exceptional strength-to-weight ratio. This makes it ideal for applications needing both robust construction and minimal weight, like: Lightweight brackets and support...1mm Titanium Sheet Price

Even at 1mm thin, titanium offers exceptional strength-to-weight ratio. This makes it ideal for applications needing both robust construction and minimal weight, like: Lightweight brackets and support...1mm Titanium Sheet Price1mm Titanium Sheet

-

Even at 2mm thickness, titanium sheet offers impressive strength while remaining significantly lighter than many other metals. This makes it ideal for applications where both robust construction and m...2mm Titanium Sheet Price

Even at 2mm thickness, titanium sheet offers impressive strength while remaining significantly lighter than many other metals. This makes it ideal for applications where both robust construction and m...2mm Titanium Sheet Price2mm Titanium Sheet

-

A 3mm titanium sheet offers a good compromise between the benefits of thinner and thicker titanium sheets.A Balancing Act of Strength, Weight, and Workability. Even at 3mm thickness, titanium sheet of...3mm Titanium Sheet Price

A 3mm titanium sheet offers a good compromise between the benefits of thinner and thicker titanium sheets.A Balancing Act of Strength, Weight, and Workability. Even at 3mm thickness, titanium sheet of...3mm Titanium Sheet Price3mm Titanium Sheet

English

English