Thank you for your

attention ON YESHENG !

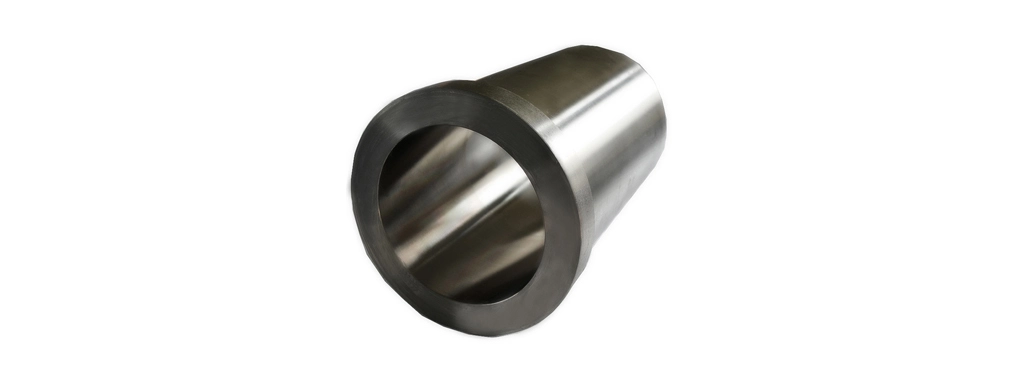

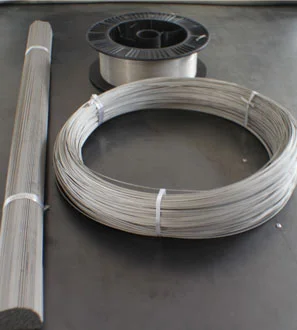

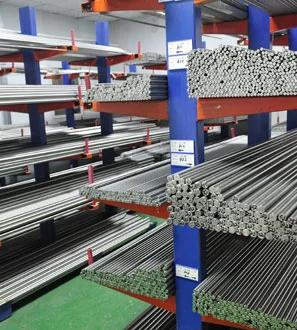

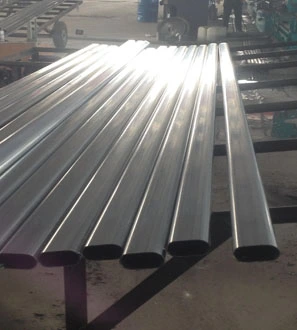

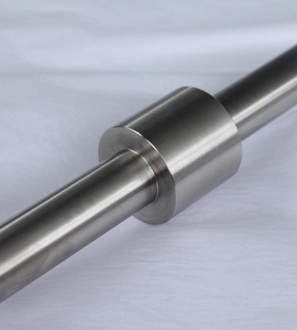

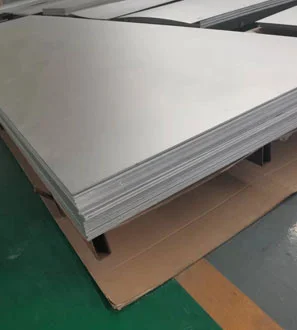

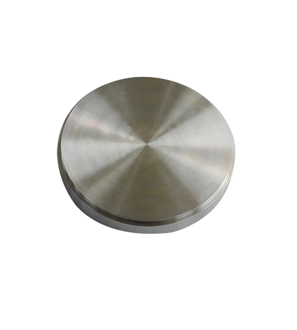

Titanium Bushing Stock for Sale

Yeshengti's Titanium Bushings showcase precision engineering, offering durability and low friction in mechanical applications. Used in automotive and machinery, these forgings ensure smooth operations, contributing to enhanced efficiency and reduced wear. For more titanium forgings in stock for sale, Contact Yeshengti.

Titanium Bushing Specification

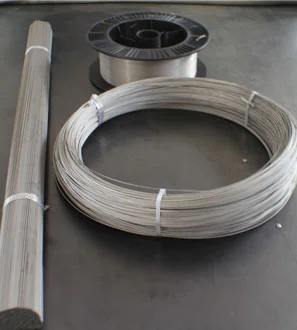

| Product Name | Titanium Bushing |

| Grade | GR1,GR2,GR5,GR5ELI,GR7,GR9,GR12,GR23,Ti-4Al-2V,Ti-4Al-1.5Mn. |

| Size | as your request |

| Standard | GB/T16598-1996、GIB2218-1994、GJB2220-1994、GJB2744-1996、GJB391-1987、GJB943-1900、ASTM B381-2005、ASTM F620-2002、AMS4924-2002、AMS4926-2001、AMS4928-2001、AMS4930-2001、AMS4965-2002、AN1S4966-2003、AMS4967-2001、ASM4973-2002、ASM4983-2002、ASN14985-2003、ASM4991-2002、MIL-F-83142-2000 、BS2TA9: 1973、BS2TA13:1974 、BS2TA24:1973 、BSTA42: 1993、BSTA51: 1993、JISH4657-1998、DIN17864-1993、NFL14-602 1984、NFL14-604 1984、NFL14-612 1984 |

| Brand Name | Yesheng |

| Application | chemical industry,Aerospace, deep sea, military, medical, etc. |

| Feature | High corrosion resistance, low density, good thermal stability,High strength and light weight. |

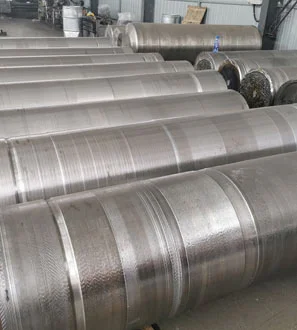

| Technics | Forging Process |

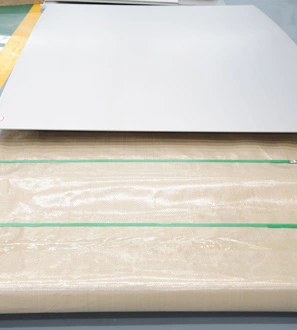

| Surface | Annealed surface, Polished surface. |

| Packing | Export Standard Woodcase |

| MOQ | as your request |

| Payment terms | T/T, Western Union, PayPal. |

| Certificate | ISO 9001:2015; The third test report. |

| Delivery time | 10—25days according to the quantity and process of the product |

| Quality and test | Ingredient testing |

| Price Term: | CIF CNF/CFR FOB Ex-work |

Advantages of using titanium bushings over other bushing materials

Titanium bushings offer several advantages over other bushing materials, making them a preferred choice in various industries.

Titanium's high strength-to-weight ratio is unparalleled, providing robustness and durability without adding significant weight. This characteristic is particularly advantageous in aerospace and high-performance vehicle applications, where reducing weight enhances fuel efficiency and performance.

Titanium bushing exhibits superior corrosion resistance, making it highly resistant to rust and degradation. This property ensures longevity and reliability, especially in harsh environments such as marine applications or exposure to chemicals where other materials may corrode or deteriorate over time.

Titanium bushing offers excellent wear resistance, prolonging the lifespan of titanium bushings. Solid titanium bushings benefit more from this attribute than flanged varieties, as they endure friction and wear more effectively, reducing maintenance needs and downtime.

The combination of high strength-to-weight ratio, superior corrosion resistance, and excellent wear resistance makes titanium bushings a versatile choice for applications requiring durable and reliable performance in challenging environments.

Solid titanium bushing vs. Flanged titanium bushing

Solid titanium bushings are ideal for general applications where a straightforward, cylindrical design effectively reduces friction between moving parts. They are commonly used in scenarios where simplicity and durability are paramount, providing reliable performance over time.

On the other hand, flanged titanium bushings are preferred when additional stability is required or to prevent the bushing from pulling out of its housing. The flange on these bushings helps distribute the load more evenly, enhancing the bushing's ability to withstand axial forces and providing better support in applications where there may be lateral movement or varying loads.

Applications for titanium bushings

As high-quality custom titanium products, titanium bushings find extensive use across diverse industries:

In aerospace, they serve in control surfaces, landing gear components, and areas requiring lightweight strength and wear resistance. Marine applications include rudders, outriggers, and control linkages exposed to saltwater. In chemical processing, titanium bushings excel in harsh chemical environments due to their corrosion resistance.

High-performance automotive sectors utilize titanium bushings for suspension components and areas needing lightweight strength and wear resistance. In the oil and gas industry, they are crucial for components requiring both strength and corrosion resistance. Titanium bushings are also used in medical devices, especially implants requiring biocompatibility and wear resistance, making them suitable for certain solid bushing applications.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский