Thank you for your

attention on Yesheng !

Introduction to the Properties and Uses of Eight Common Metal Materials

1、Cast Iron – Fluidity

Manhole covers, often overlooked in our daily environment, are made extensively from cast iron primarily due to its excellent fluidity and ease of casting into various complex shapes. Cast iron is actually a mixture of several elements, including carbon, silicon, and iron. The higher the carbon content, the better its fluidity during the casting process. Carbon appears in cast iron in the form of graphite and iron carbide.

The presence of graphite in cast iron gives manhole covers excellent wear resistance. Rust typically only forms on the surface and is usually polished off. However, anti-rust measures are still applied during the casting process, such as coating the cast iron surface with a layer of asphalt, which penetrates the pores of the cast iron and acts as a rust inhibitor. The traditional process of sand mold casting is now used by many designers in other new and interesting fields.

Material Characteristics: Excellent fluidity, low cost, good wear resistance, low solidification shrinkage, brittle, high compressive strength, good machinability.

Typical Uses: Cast iron has been used for centuries in architecture, bridges, engineering components, home furnishings, and kitchen utensils.

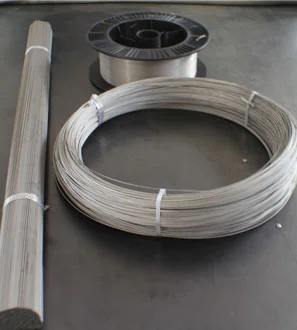

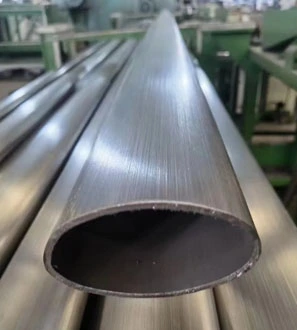

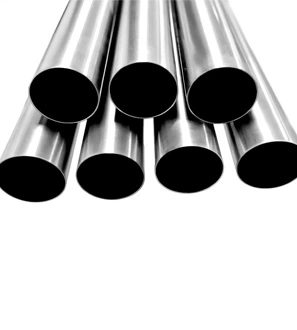

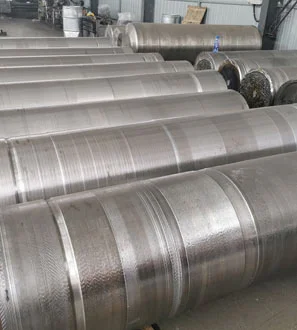

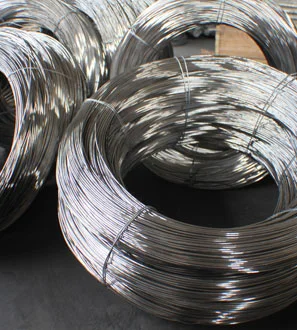

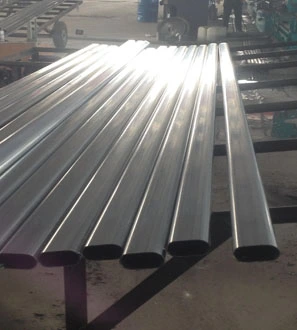

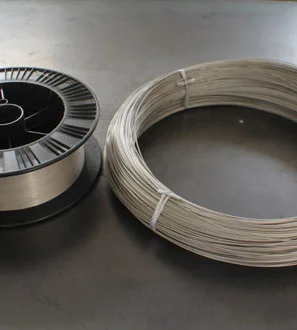

2、Stainless Steel – The Love for Rust Resistance

Stainless steel is an alloy made by adding chromium, nickel, and other metal elements to steel. Its rust-resistant property comes from the chromium content in the alloy, which forms a strong, self-healing layer of chromium oxide on the surface, invisible to the naked eye. The ratio of chromium to nickel in common stainless steel is usually 18:10. The term "stainless steel" does not refer to a single type of stainless steel but to over a hundred types of industrial stainless steels, each developed for specific applications.

Stainless steel was introduced into product design in the early 20th century. Designers have developed many new products around its toughness and corrosion resistance, entering fields that had never been explored before. These design attempts were revolutionary: for example, sterilizable and reusable equipment first appeared in the medical industry.

Stainless steel is divided into four main types: austenitic, ferritic, duplex (ferritic-austenitic), and martensitic. The stainless steel used in household items is mostly austenitic.

Material Characteristics: Hygienic, corrosion-resistant, capable of fine surface treatment, high rigidity, can be shaped through various processing methods, difficult to cold work.

Typical Uses: Austenitic stainless steel is the most suitable material for coloring and can achieve satisfactory color and shape. It is mainly used in decorative building materials, household items, industrial piping, and construction structures. Martensitic stainless steel is primarily used to make tools and turbine blades. Ferritic stainless steel, with its corrosion resistance, is mainly used in durable washing machines and boiler components. Duplex stainless steel, with its superior corrosion resistance, is often used in corrosive environments.

3、Zinc – 730 Pounds in a Lifetime

Zinc, with its silvery-blue appearance, is the third most widely used non-ferrous metal after aluminum and copper. According to statistics from the U.S. Geological Survey, an average person consumes a total of 331 kilograms of zinc in their lifetime. Zinc has a low melting point, making it an ideal casting material.

Zinc castings are very common in our daily lives: the materials beneath door handles, faucets, and electronic components are often made of zinc, which has excellent corrosion resistance. This property also makes it a basic material for coating steel surfaces. Beyond these uses, zinc is also an alloying material with copper to form brass. Its corrosion resistance is not only applied to steel coatings—it also helps boost the human immune system.

Material Characteristics: Hygienic, corrosion-resistant, excellent castability, outstanding corrosion resistance, high strength, high hardness, inexpensive raw materials, low melting point, creep-resistant, easily forms alloys with other metals, beneficial to health, brittle at room temperature, ductile at around 100°C.

Typical Uses: Electronic components, one of the alloying materials in bronze, roofing materials, photogravure plates, mobile phone antennas, and camera shutters.

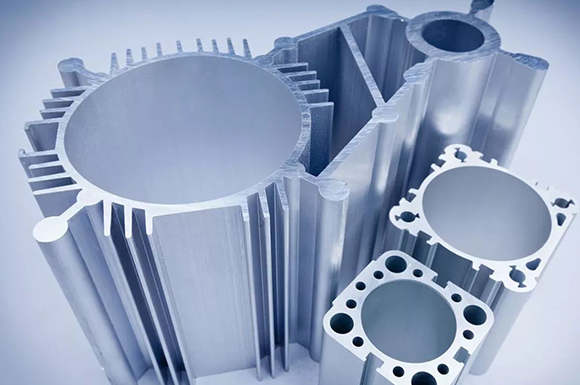

4、Aluminum (Al) – The Modern Material

Compared to gold, which has been used for 9,000 years, aluminum—a slightly bluish-white metal—can be considered a newcomer among metals. Aluminum was discovered and named in the early 18th century. Unlike other metal elements, aluminum does not exist in nature in its metallic form but is extracted from bauxite, which contains 50% aluminum oxide (also known as alumina). In this form, aluminum is one of the most abundant metal elements on Earth.

When aluminum was first discovered, it was not immediately used in everyday life. Later, a series of new products were developed that capitalized on its unique functions and properties, and this high-tech material gradually gained a broader market. Although aluminum has a relatively short history of use, its production volume on the market now far exceeds the total output of other non-ferrous metal products.

Material Characteristics: Ductile, easily alloyed, high strength-to-weight ratio, excellent corrosion resistance, conductive, thermally conductive, recyclable.

Typical Uses: Structural frameworks for transportation, aircraft components, kitchen utensils, packaging, and furniture. Aluminum is also used to reinforce large architectural structures, such as the Eros statue in Piccadilly Circus, London, and the top of the Chrysler Building in New York.

5、Magnesium Alloy – Ultra-Thin Aesthetic Design

Magnesium is a highly important non-ferrous metal, lighter than aluminum, and forms high-strength alloys with other metals. Magnesium alloys have advantages such as lightweight structure, high specific strength and stiffness, good thermal and electrical conductivity, excellent damping and shock absorption properties, easy formability, and easy recyclability. However, due to high costs and technical limitations, magnesium and its alloys have long been used in small quantities in the aerospace, military, and aviation industries, hence being referred to as "noble metals." Today, magnesium is the third most commonly used engineering metal after steel and aluminum, widely applied in aerospace, automotive, electronics, mobile communications, and metallurgy. Due to the rising production costs of other structural metals, magnesium's importance is expected to grow in the future.

Magnesium alloys weigh 68% as much as aluminum alloys, 27% as much as zinc alloys, and 23% as much as steel, and are commonly used in automotive parts, 3C product housings, and building materials. Most ultra-thin laptop and mobile phone housings are made from magnesium alloy. Since the last century, there has been an undiminished passion for the texture and luster of metals. Although plastic products can mimic the appearance of metals, they still lack the luster, hardness, temperature, and feel of real metals. Magnesium alloy, as a new metal material, gives a high-tech product feel.

The corrosion resistance of magnesium alloy is eight times that of carbon steel, four times that of aluminum alloy, and more than ten times that of plastic, making it the best corrosion-resistant alloy. Common magnesium alloys are non-flammable, especially when used in automotive components and building materials, to prevent instant combustion. Magnesium ranks eighth in abundance in the Earth's crust, with most magnesium raw materials being extracted from seawater, so it is a stable and abundant resource.

Material Characteristics: Lightweight structure, high rigidity, impact resistance, excellent corrosion resistance, good thermal conductivity and electromagnetic shielding, non-flammable, poor heat resistance, recyclable.

Typical Uses: Widely used in aerospace, automotive, electronics, mobile communications, and metallurgy.

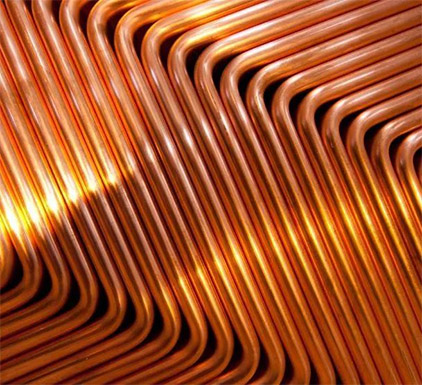

6、Copper – Humanity's Companion

Copper is an incredibly versatile metal, intimately linked to our lives. Many early human tools and weapons were made of copper. Its Latin name "cuprum" comes from a place called Cyprus, a copper-rich island, and the abbreviation "Cu" is derived from the island's name, giving copper its current symbol.

Copper plays a crucial role in modern society: it is widely used in construction structures, as a carrier for transmitting electricity, and for thousands of years, it has been used by various cultures as a material for body ornaments. From simple code transmission to complex modern communications applications, this ductile, reddish metal has accompanied our development. Copper is an excellent conductor of electricity, second only to silver. In terms of the length of time humans have utilized metal materials, copper is second only to gold as one of the oldest metals used by humans. This is largely because copper mines are easy to extract and copper can be easily separated from its ore.

Material Characteristics: Excellent corrosion resistance, outstanding thermal and electrical conductivity, hard, flexible, ductile, and provides a unique effect when polished.

Typical Uses: Electrical wires, engine coils, printed circuits, roofing materials, plumbing materials, heating materials, jewelry, cookware, and as a primary alloying component in bronze.

7、Chromium – High Gloss Post-Processing

Chromium is most commonly used as an alloying element in stainless steel to increase its hardness. Chromium plating typically comes in three types: decorative plating, hard chromium plating, and black chromium plating. Chromium plating is widely used in engineering, with decorative chromium plating usually applied as the outermost layer over nickel plating, providing a delicate, mirror-like polished finish. As a decorative post-processing technique, the thickness of the chromium plating is only 0.006 millimeters. When considering chromium plating, it is essential to be aware of its dangers. Over the past decade, hexavalent decorative chromium solutions have increasingly been replaced by trivalent chromium solutions due to the former's strong carcinogenicity, while the latter is considered relatively less toxic.

Material Characteristics: Extremely high gloss, excellent corrosion resistance, durable, easy to clean, hygienic, costly, highly toxic during processing.

Typical Uses: Automotive parts, sanitary ware, architectural hardware, knives and forks, kitchen utensils, hand tools, electrical appliances, timepieces, and jewelry.

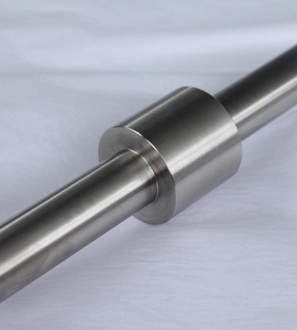

8、Titanium – The Lightest Metal

Titanium has the highest strength-to-weight ratio among common metal materials. It is known as "the lightest metal," and its strength and hardness far exceed that of aluminum, copper, and stainless steel. Its density is only 60% of that of steel, yet it possesses comparable strength. Titanium and its alloys have been widely used in the aerospace, automotive, construction, sports, and other fields since the 1960s. Although titanium has excellent characteristics, its application has been limited for a long time due to the need for sophisticated equipment in the extraction process and the high production costs.

With the advancements in extraction technology and the reduction in production costs, the industrial production of titanium has gradually expanded from the initial defense and aviation industries to other industries. In addition to their low density and high strength, titanium alloys also have outstanding corrosion resistance and excellent welding performance, making them a perfect material for sports equipment like golf clubs and bicycles, ensuring they maintain their luster under various weather conditions. They are also widely used in medical devices like orthopedic implants and dental implants due to their good biocompatibility.

Material Characteristics: Lightweight, corrosion-resistant, good ductility, high strength-to-weight ratio, high cost.

Typical Uses: High-performance products such as spacecraft, rockets, aircraft, automotive parts, and various sports equipment. Titanium is also used in daily-use metals, such as golf clubs, glasses frames, knives and forks, and watches.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский