Thank you for your

attention on Yesheng !

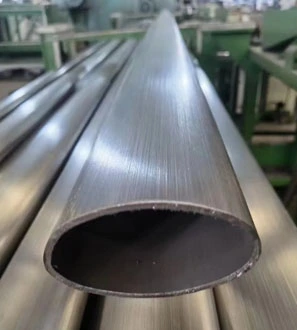

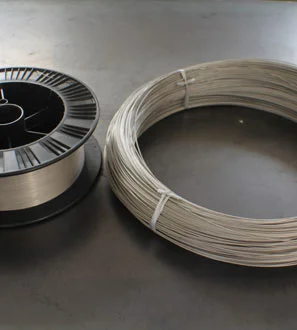

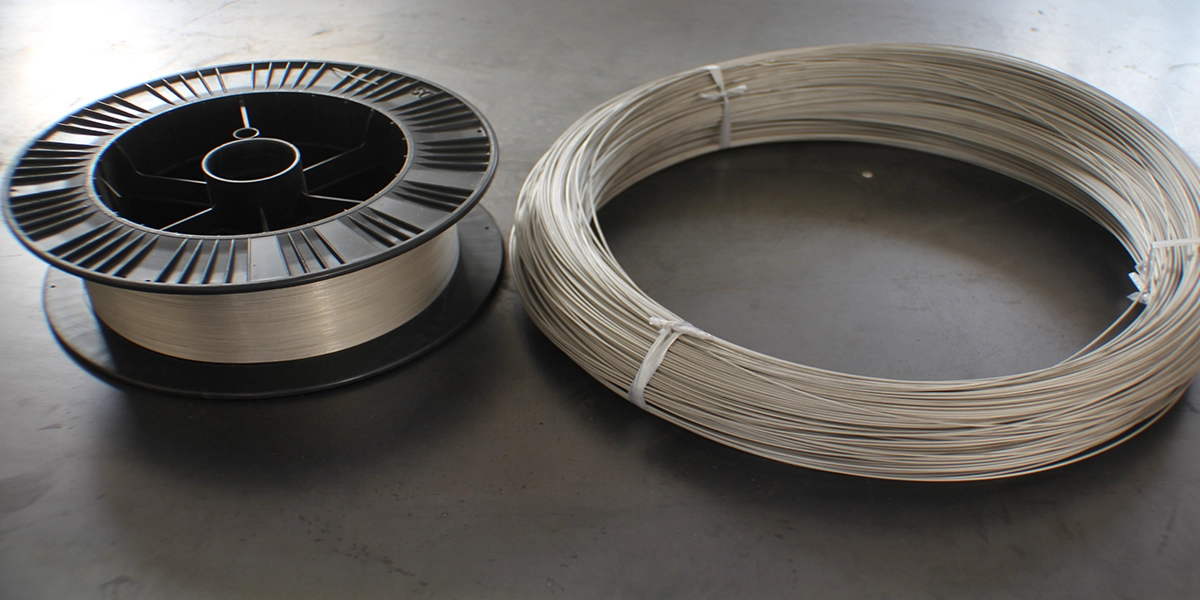

Rolling Process for Titanium and Titanium Alloy Wires

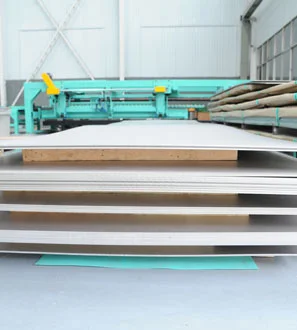

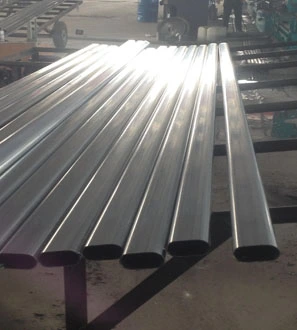

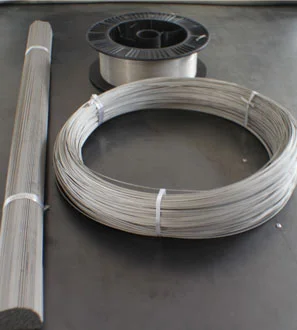

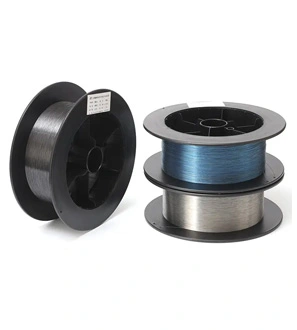

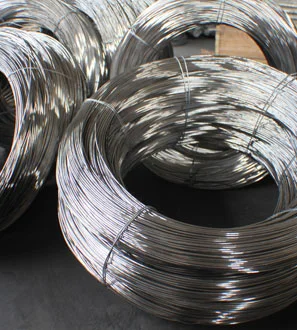

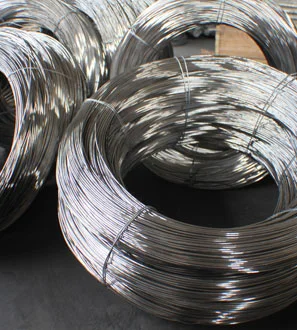

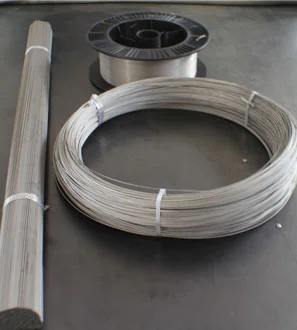

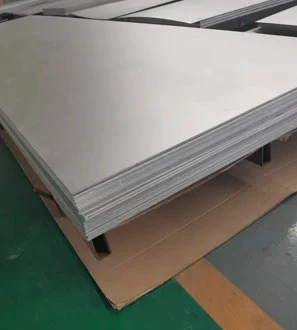

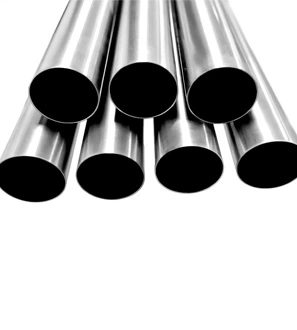

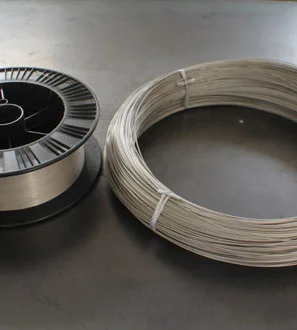

The rolling of titanium and titanium alloy wires involves the use of titanium and titanium alloy billets (either in coils or as single rods) as raw materials. These billets are drawn into coil or single wire products. This process encompasses a variety of products, including iodide titanium wire, titanium-molybdenum alloy wire, titanium-tantalum alloy wire, industrial pure titanium wire, and other titanium alloy wires. Iodide titanium wire is used in industries such as instrumentation, electronics, and other industrial sectors. The Ti-15Mo alloy wire serves as a getter material for ultra-high vacuum titanium ion pumps, while the Ti-15Ta alloy wire is used as a getter material in ultra-high vacuum industrial sectors. Industrial pure titanium and other titanium alloy wires include products like industrial pure titanium wire, Ti-3Al wire, Ti-4Al-0.005B wire, Ti-5Al wire, Ti-5Al-2.5Sn wire, Ti-5Al-2.5Sn-3Cu-1.5Zr wire, Ti-2Al-1.5Mn wire, Ti-3Al-1.5Mn wire, Ti-5Al-4V wire, and Ti-6Al-4V wire. These are used for corrosion-resistant parts, electrode materials, welding materials, and high-strength TB2 and TB3 alloy wires, which are applied in the aerospace and aviation sectors.

Process Parameters for Rolling Titanium and Titanium Alloy Wires

1、Heating System and Finishing Rolling Temperature:

①For β-type titanium alloys, the pre-rolling heating temperature is slightly lower than the (α+β)/β phase transition temperature. The rolling process is completed within the α+β phase region.

②α+β titanium alloys are heated within the α+β phase region.

③For β-type titanium alloys, the heating temperature is higher than the β transition temperature. The heating time is calculated based on 1-1.5 mm/min. The pre-rolling heating temperature of titanium and titanium alloy billets and the finishing rolling temperature of the profiles are roughly the same as the final milk temperature of the rolled bars.

2、Selection of Other Process Parameters:

Due to the high production volume of titanium and titanium alloy rolled profiles, the product length should not be too short, and the rolling speed should not be too high. In actual production, the rolling speed is generally between 1-3 m/s.

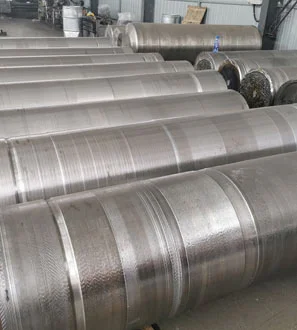

3、Roll Pass Design:

Based on the deformation resistance, spread value, and elongation of the titanium alloy, appropriate roll passes for various steel profiles are selected to roll the titanium alloy profiles. If the batch size of the titanium alloy profiles is large, roll passes can be designed specifically for titanium alloys based on their characteristics to produce the profiles.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский